Internal order

For staff members requiring items to work, the internal order is the document of choice to communicate their demand.

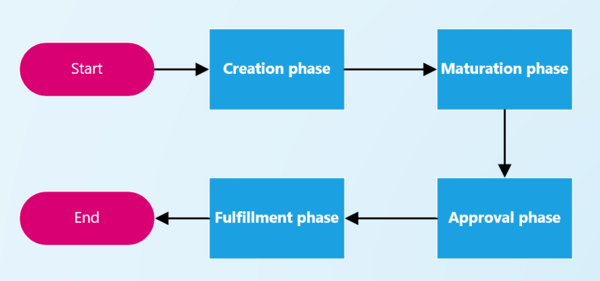

Phases of an internal order

Creation phase

For the creation phase, we have designed our shop solution to file the internal order. Typically two use cases can be differentiated:

- the user knows the exact items which are required, picks a product listed in the shop. We call this a fully qualified product position Example: I want product "HP 17-Cp0212ng".

- the user knows only his general demand, but does not know which products are the right ones. We call this a purchase requisition position Example: I want a "bike with 20 inch wheels"

Internal orders can be filed directly or can be the result of a purchase requisition being processed by a procurement officer.

Examples for internal orders

This offers a rapid process for employees to fill their demand on items required for their work (e.g. for c-parts). Typical products for this process are c-parts like tools, personal protective equipment (ppe) or corporate wear. The processual outcome of the shopping process is either an internal order, a purchase order or a customer order.

Internal order flow

Purchase requistion (freetext) --> internal order --> fulfillment

Fulfillment of internal orders

Once the demand is filed, companies have two decide between two core fulfillment strategies:

- stock fulfillment - means the fastest availability of goods. Downsides are capital binding, warehousing and disposition planning costs.

- On demand purchasing - means slower availability and direct dependency on supplliers. Benefit is the reducion of warehousing cost. Capital binding and disposition planning can be negotiated with the suppliers.

General Process Flow

- Ordering

- "AdHoc purchasing" vs "Local Fulfillment"

Process "Just in time ordering"

Gathering and grouping of demand

Clearance process

Purchaing with supplier

Fulfillment

Billling

Process "Local Warehousing"

Problems

Maverick buying

distributed clearance process require process guidance - especially material clearance

Combination of "Just in time process vs. bulk ordering

warehousing in bulk ordering