Difference between revisions of "C parts"

Stefanseiler (talk | contribs) |

Stefanseiler (talk | contribs) |

||

| Line 1: | Line 1: | ||

[[File:C-parts statistics.png|thumb]] It is clear that screws, nuts, bolts and washers can be components of secondary importance to an industrial system or machine. However, it goes without saying that C-Parts are essential for your end product. | [[File:C-parts statistics.png|thumb|600x600px]] It is clear that screws, nuts, bolts and washers can be components of secondary importance to an industrial system or machine. However, it goes without saying that C-Parts are essential for your end product. | ||

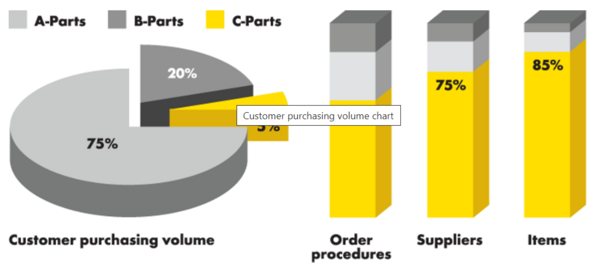

The purchasing volume of C-Parts is typically very low. On average, C-Parts only make up 5% of the purchasing volume in production, however, the procurement costs are very high (at least 75% of your expenditure). This particularly applies during high levels of demand. Coordinating these items and handling repeat orders can be very overwhelming for industrial manufacturing companies where C-Parts Inventory Management has not been implemented. | The purchasing volume of C-Parts is typically very low. On average, C-Parts only make up 5% of the purchasing volume in production, however, the procurement costs are very high (at least 75% of your expenditure). This particularly applies during high levels of demand. Coordinating these items and handling repeat orders can be very overwhelming for industrial manufacturing companies where C-Parts Inventory Management has not been implemented. | ||

There are a lot of steps like material flows and processes you need in order to make a C-Part available precisely when it is needed. | There are a lot of steps like material flows and processes you need in order to make a C-Part available precisely when it is needed. | ||

Revision as of 05:23, 30 May 2022

It is clear that screws, nuts, bolts and washers can be components of secondary importance to an industrial system or machine. However, it goes without saying that C-Parts are essential for your end product.

The purchasing volume of C-Parts is typically very low. On average, C-Parts only make up 5% of the purchasing volume in production, however, the procurement costs are very high (at least 75% of your expenditure). This particularly applies during high levels of demand. Coordinating these items and handling repeat orders can be very overwhelming for industrial manufacturing companies where C-Parts Inventory Management has not been implemented.

There are a lot of steps like material flows and processes you need in order to make a C-Part available precisely when it is needed.