Difference between revisions of "C parts"

Stefanseiler (talk | contribs) (Created page with "It is clear that screws, nuts, bolts and washers can be components of secondary importance to an industrial system or machine. However, it goes without saying that C-Parts are essential for your end product. The purchasing volume of C-Parts is typically very low. On average, C-Parts only make up 5% of the purchasing volume in production, however, the procurement costs are very high (at least 75% of your expenditure). This particularly applies during high levels of deman...") |

Stefanseiler (talk | contribs) |

||

| (2 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

It is clear that screws, nuts, bolts and washers can be components of secondary importance to an industrial system or machine. However, it goes without saying that C-Parts are essential for your end product. | [[File:C-parts statistics.png|thumb|600x600px]] It is clear that screws, nuts, bolts and washers can be components of secondary importance to an industrial system or machine. However, it goes without saying that C-Parts are essential for your end product. | ||

The purchasing volume of C-Parts is typically very low. On average, C-Parts only make up 5% of the purchasing volume in production, however, the procurement costs are very high (at least 75% of your expenditure). This particularly applies during high levels of demand. Coordinating these items and handling repeat orders can be very overwhelming for industrial manufacturing companies where C-Parts Inventory Management has not been implemented. | The purchasing volume of C-Parts is typically very low. On average, C-Parts only make up 5% of the purchasing volume in production, however, the procurement costs are very high (at least 75% of your expenditure as you need for each product group you are procuring knowledge on the material, staff to hold this, warehousing cost, ... ). This particularly applies during high levels of demand. Coordinating these items and handling repeat orders can be very overwhelming for industrial manufacturing companies where C-Parts Inventory Management has not been implemented. | ||

There are a lot of steps like material flows and processes you need in order to make a C-Part available precisely when it is needed. | There are a lot of steps like material flows and processes you need in order to make a C-Part available precisely when it is needed. | ||

Latest revision as of 05:24, 30 May 2022

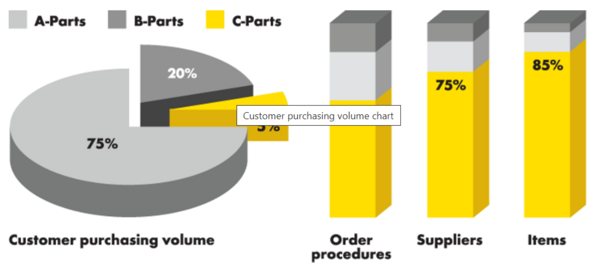

It is clear that screws, nuts, bolts and washers can be components of secondary importance to an industrial system or machine. However, it goes without saying that C-Parts are essential for your end product.

The purchasing volume of C-Parts is typically very low. On average, C-Parts only make up 5% of the purchasing volume in production, however, the procurement costs are very high (at least 75% of your expenditure as you need for each product group you are procuring knowledge on the material, staff to hold this, warehousing cost, ... ). This particularly applies during high levels of demand. Coordinating these items and handling repeat orders can be very overwhelming for industrial manufacturing companies where C-Parts Inventory Management has not been implemented.

There are a lot of steps like material flows and processes you need in order to make a C-Part available precisely when it is needed.