Rolling stocktaking

Rolling stocktaking, also known as continuous or perpetual stocktaking, is a dynamic approach to inventory management where the counting and verification of inventory occur continuously throughout the year, as opposed to a periodic, fixed-time schedule. In this process, small sections of the inventory are counted regularly, allowing for more frequent updates and adjustments to stock levels. This method is particularly useful for businesses that require real-time visibility into their inventory and want to minimize disruptions caused by large-scale stocktaking events.

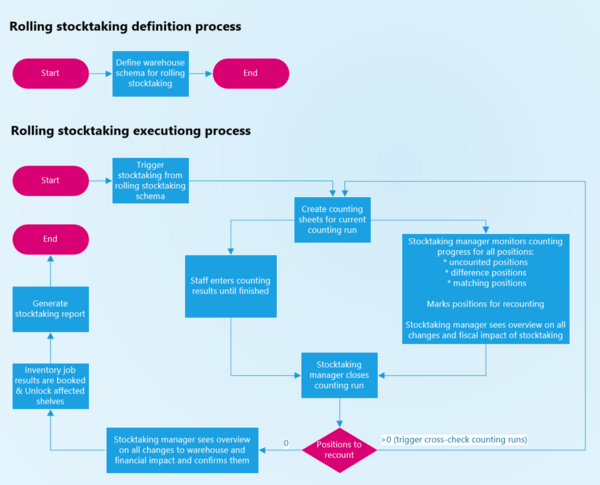

Here's how the rolling stocktaking process generally works:

- Establish a Baseline:

- Begin with a comprehensive stocktake to establish an accurate baseline of the current inventory levels. This involves physically counting all items in stock and reconciling this information with the inventory records.

- Continuous Counting:

- Divide the entire inventory into smaller sections or categories.

- Assign different sections to different teams or individuals responsible for continuous counting. These counts can be performed daily, weekly, or monthly, depending on the size and nature of the inventory.

- Real-time updates: Ensure that the inventory management system is updated in real-time as items are counted, allowing for immediate visibility into stock levels.

- Adjustments and Documentation:

- Make adjustments: Update the inventory records based on the results of continuous counting and reconciliation.

- Document changes: Keep detailed records of adjustments, including the reasons for discrepancies and the actions taken to rectify them.

Rolling stocktaking offers the advantage of minimizing the disruption caused by large-scale stocktakes while providing a more accurate and up-to-date picture of inventory levels. This real-time visibility helps businesses make informed decisions and respond quickly to changes in demand or supply.